So lets talk about 3D printers and their fumes. I’ve been heavily into 3D printing for about 2 and a half years, first building a Prusa i3 clone and later buying an Ultimaker 3. One of the things that has always bothered me was the possibility of toxic fumes. About 2 years ago, a study came to light that, yes, indeed, 3D printers do emit things that aren’t good for you. There was a lot of discussion about it around that time, but it seems to have died down.

Disclaimer: Before we continue, I must first confess I do not possess the right credentials to perform any kind of proper scientific study into air quality. Consider me a concerned citizen and if you do have the proper background, please get in touch, I’d love to cooperate to get to the bottom of this.

Introduction

You can read the full study here and a number of follow-up experiments on the dedicated page of the Built Environment Research Group, which has performed the studies.

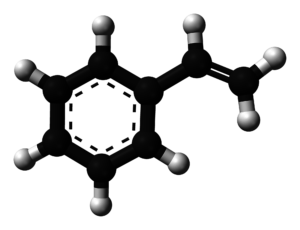

To summarize it very briefly, they found that all filaments emit ultra fine particles (UFP, in the range of 10 nano meter (nm) to 0.1 micro meter) and volatile organic compounds (VOCs, one of those, styrene is very likely carcinogenic, while others are currently uncertain but suspect)

Most amounts exhausted are most likely of no great concern. For instance, the UFPs were in the range of other indoor activities, such as cooking. So as long as you are in a ventilated place, you should be fine. However, some precautions never hurt any one.

The styrene that was emitted by ABS is worrisome. And if you print a lot with ABS, you should probably make sure you somehow extract the fumes or are not in the same room for too long. Other VOCs are harmless, while still others, we just don’t know, so it’s better to safe than sorry.

Measuring UFPs

If you want to measure ultrafine particles at home, you’re going to have to shell out some serious cash. I was not able to locate equipment that was affordable or did not have a “call us” button instead of a price.

The best I could do (and I know, this is very unscientific) is a PM2.5 sensor. These devices measure particles from about 100 nm up to 2.5 micro m. So they are not perfect, but at least they measure the higher range of the UFP sizes.

I ordered one anyway. (As a side-note, my main criteria was that it actually had to look real. There are a lot of things on AliExpress that look like concept art. I have no idea what you’ll get when you order one of those)

<figcaption class="wp-caption-text">Seriously, there’s no way the real thing even remotely looks like this. I almost ordered it to see what would actually be delivered.</figcaption></figure>

<figcaption class="wp-caption-text">Seriously, there’s no way the real thing even remotely looks like this. I almost ordered it to see what would actually be delivered.</figcaption></figure>

I doubt a $45 device is properly calibrated, but at least, it should give an idea of relative values, or how much more particles there are in the air while printing. So don’t spend too much time looking at the absolute numbers, focus on the relatives.

The main downside of those devices is that you are not able to get their readings and store them permanently, so it’s impossible to log the values over longer time.

As a baseline, I’ve done measurements on random days in my office. The office is connected to a home ventilation system, so it continuously gets fresh and filtered air. Obviously, these initial measurements were taken when the printer had not printed for at least 12 hours. The readings varied between about 5 and 15 micrograms/m³. The higher reading was on a hot, sunny day that had no wind.

When I went outside on that day, it was even worse:

So if you’re scared for particles, better to stay indoors when it’s hot outside.

With the printer working (printing PLA and a bit of PVA), I consistently saw an increase. Usually around 5 microg/m³.

I got similar results on different days with different weather conditions. Almost always, the number of particles outside was more than inside while the printer was active, but there was a slight increase of particles inside the office.

So it looks like this kind of pollution is in line with the original paper. I would not want to hang around in a room where multiple printers are constantly printing, but a hobby printer that’s on from time to time seems to be ok.

And if you’re still worried (you should be!), there’s an easy precaution you can take to alleviate the potential risk. But first, lets take a look at VOCs.

Measuring VOCs

Similar to the UFPs, I was not able to find a device that can measure specific types of VOCs for any reasonable price. So I took another road. If you want to thinker, there are many boards available that allow you to measure the total amount of VOCs.

I bought this Adafruit SGP30 board and combined it with a Wemos Lolin clone I had lying around.

Again very similar to the UFP measurement devices, I very much doubt I was able to properly calibrate it, but I did follow the guide (leave if running for 12 hours and store the baseline every hour). So again, the relative values should be ok to interpret.

Note: I hope to write an entire post about this setup and open source the code in the near future. There’s just one more thing I want to add to the code before I consider it sort-of done 😉

<figcaption class="wp-caption-text">My setup: output is directly displayed on the screen. I’m working on an extension to log the measurements and run experiments over longer time windows.</figcaption></figure>

<figcaption class="wp-caption-text">My setup: output is directly displayed on the screen. I’m working on an extension to log the measurements and run experiments over longer time windows.</figcaption></figure>

Measurements of the total VOCs varied widely. Anything between 5 and 200 parts per billion (ppb) (again, hot and sunny days seem to be worse). Even within an hour, there were large 50+ variations.

When printing, I was not able to see a rise in the numbers. At least nothing that seemed out of the normal variations I had seen.

Even when I tried printing ABS, I was not able to see a meaningful increase in the numbers. Since the Ultimaker is an open printer, I’m guessing the particles were mixed into the air and concentration became too low to measure. If you dissolve 50 microgram/minute into the volume of my office (about 40m³) and combine it with the constant inflow of fresh air, I can imagine it’s hard to measure something in parts per billion.

I plan to add an enclosure to my printer combined with a fan that sucks the printers air and redirects it to the sensor. That should give better measurements.

So the jury is still out on this one.

Filtering UFPs and VOCs

The next thing one wants to do, is of course get rid of these things.

HEPA filters can help with filtering UFPs. Although they work better with slightly larger particles, they are also somewhat effective for smaller sizes. Given that the UFP concentration is already around fairly normal values, this is good enough for me. For now at least.

VOCs can be filtered by activated carbon or charcoal. You’ll usually find these as granules or as foam impregnated with powder.

Both of these items are dirt cheap, so, of course, I built a filter.

Thingiverse has multiple designs, but I chose to build this one. Mostly because it has room for both an activated carbon filter and a HEPA filter. Furthermore, it’ uses off-the-shelf parts that you can source from AliExpress or other places easily and it has a large fan, which means it doesn’t make as much noise as some of those small fans.

The design is not perfect, but it’s ok. I was not able to use the grill that should go on the HEPA filter. It needs tiny but very long screws and it’s not needed anyway. I think It’s also quite easy to redesign so it doesn’t need as much plastic by not completely encasing the fan. Something along those lines. You’re probably only going to print this once, so it’s not that important.

So how does it work? Actually really good for particles. As before, the baseline with the fan turned off was around 20 microg/m³:

With fan on the exhaust has much cleaner air:

That’s the good news.

As for TVOC measurements: I saw very little difference between intake and exhaust ppb readings. I’m a bit suspicious of the activated carbon foam. I’m not sure I bought the good stuff. And I also need to figure out my measuring techniques by doing longer time measurements. So again, I’m not sure what to think of this and more work is needed.

Conclusion

While the measured VOCs and UFPs when printing PLA was small and does not present an immediate danger, it’s a very good idea to be vigilant. Regularly, scientific studies appear that link a number of health issues with these pollutants.

So I would suggest every one who is 3D printing to at least make sure the room is ventilated, drawing in fresh air. If possible, add an air filter. You can build one very cheap, so it is a no-brainer.

Finally, you can put your printer in an enclosure. It’s something I plan to do, just to err on the safe side.

If I didn’t make myself clear at the start: I know barely enough to be dangerous and much more study is required. In general, I’m saddened that only few people and companies are investigating this further. Most prefer to ignore it. If you want to help out. Please get in touch (use Facebook or Twitter, the contact form is a spam trap and not very regularly checked).